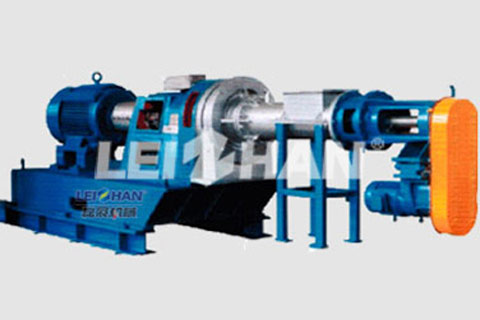

Disc Disperser for Paper Making Line

Disc disperser machine is mainly used in the heat dispersion section of pulp and paper industry, the pulp knead dispersion, remove stickies, asphalt, paraffin, plastic, ink particles and other impurities in the slurry, to ensure that the paper machine normal operation, improve the appearance quality of paper, in high temperature, high concentration, high-speed processing, the fiber bifurcated wire points to improve the pulp beating degree, improve the paper evenness.

Leizhan Disc disperser advantages

1. Disc disperser machine static and dynamic disc clearance adjustable to 0.01mm, strong dispersion of adhesive, asphalt, paraffin, plastic, ink particles and other impurities, the effect is significant.

2. Disc disperser machine has the best dispersion to deal with a variety of hot-melt adhesives in high temperature, high concentration, high-speed conditions.

3. Disc disperser machine has the best dispersion to deal with a variety of refractory ink particles, such as laser printing ink, xerographic ink, UV solid ink in high temperature, high concentration, high-speed conditions.

4. Disc disperser in the high temperature, high concentration, high-speed conditions, the fibers bifurcated wire can improve the beating degree of pulp, improve the strength and evenness of paper, improve the appearance of paper quality.

5. In DIP pulping, adding chemicals before Disc disperser, can improve the bleaching effect.

6. Adapt to a wide range of slurry species, OCC, AOCC, ONP, OMG, MOW and other slurry can be used.

7. With the Screw press washer, plug screw, broken screw, heating screw with the use of PLC automation and hydraulic control, more stable performance, better dispersion, steam more savings. machine in high temperature, high concentration, high-speed conditions, the deal with a variety of hot-melt adhesives, the best dispersion.