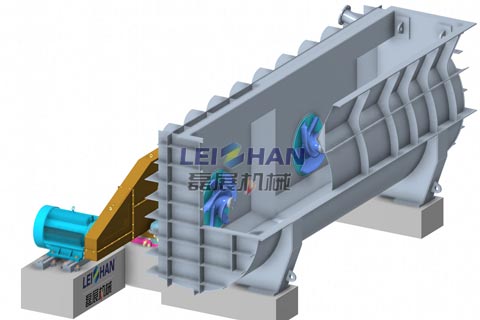

SZS Broken Paper Pulper

The SZS type of Broken Paper Pulper is mainly used to deal with the broken paper generated in various paper machines such as pressing, calendering and coiling. The main advantages of this type of loss pulper are: the use of an optimized rotor shape can achieve a high turbulence effect with the lowest power consumption; a high suction rate greatly increases the friction between the fibers, so that the pulp is broken The solution does not only rely on the mechanical force between the rotor and the sieve plate. At the same time, it is supplemented by a new pulp tank structure, which improves the contact frequency between the rotor and the pulp to a certain extent.

| Type | SZS1 | SZS2 | SZS3 | |

| Rotor diameter(mm) | 750 | 1000 | 1300 | |

| Good pulp outlet(DN) | 300 | 400 | 500 | |

| Volume of pulp chest(m³) | 5.5-15 | 14-33 | 31.5-80 | |

| Width of pulp chest(mm) | 2500-5000 | 3500-6000 | 4500-8000 | |

| Pulp concentration(%) | 3-5 | |||

| Sieve Size(mm) | 10-24 | |||

| Matching motor power(KW) | 45-160 | 90-355 | 200-630 | |

- The main structure of Broken Paper Pulper:

The SZS type Broken Paper Pulper is mainly composed of matching slurry tank, rotor, sieve plate, transmission device, driving device and transmission guard.

1. Pulp Chest

As the slurry tank matched with the SZS broken paper pulper, customers can use the traditional concrete slurry tank. The cross-sectional size of the slurry tank needs to be poured according to the size provided by our company; the steel slurry tank provided by our company can also be used. Both have the same effect.

2. Rotor device

This type of damaged paper pulper uses a double-acting rotor structure. The installed rotor is higher than the side of the slurry tank. When the rotor rotates, mechanical force is generated between a part of the blades and the sieve plate to break up the fibers; A part of the blades produces a suction effect, and under the coordination of the shape of the slurry tank, the friction between the fibers is strengthened.

3. Sieve plate device

In order to facilitate disassembly and assembly, the screen device adopts a split structure design and is fixed with special bolts to avoid long-term erosion and wear of the fixing bolts by the slurry flow.

4. Transmission

The transmission part of the SZS Broken Paper Pulper adopts the design of two sets of spherical roller bearings at the front and rear; in addition to the fixing bolts, the bearing seat is also designed with positioning pins, which is convenient for customers to install the bearings in the correct position after maintenance. .

5. Driving device

This type of Broken Paper Pulper is driven by a motor, and the motor is fixed on a

The separate concrete foundation avoids the impact of the vibration of the motor on the equipment.

6. Transmission guard

This type of Broken Paper Pulper adopts belt transmission, so it is equipped with a guard to remove the entire leather

The belt is partially completely wrapped, and the shield is fixed to the equipment base by bolts.